Calculation of Cost

By clicking on the button, you consent to the processing of personal data and agree to the privacy policy.

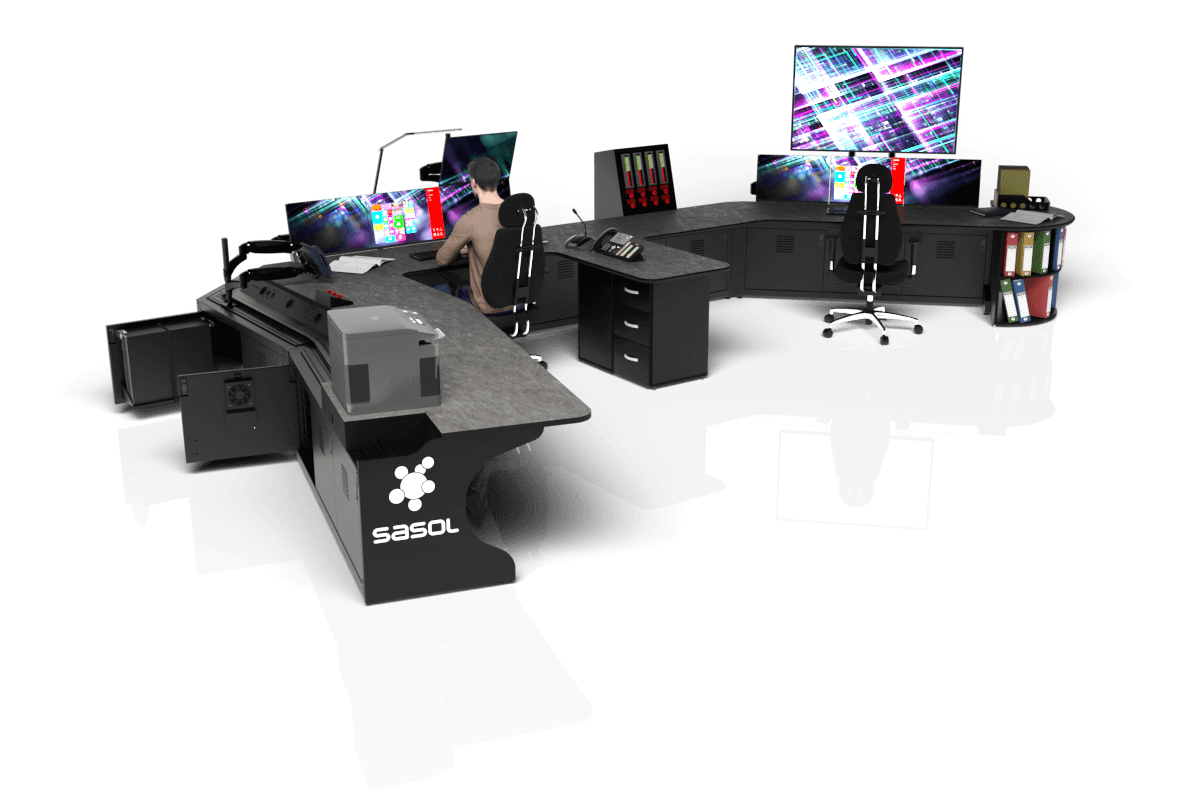

We create comfortable workspaces for dispatchers and operators in monitoring and

dispatch centers that operate 24/7/365. We implement the project from initial inquiry

to final assembly at the customer's site.

We make photorealistic sketches of workplaces at each stage of the process, with

elaboration of nuances and details.

dispatch centers that operate 24/7/365. We implement the project from initial inquiry

to final assembly at the customer's site.

We make photorealistic sketches of workplaces at each stage of the process, with

elaboration of nuances and details.

Control Room Consoles & Technical Furniture RDM

Control Room Consoles & Technical Furniture RDM

We create comfortable workspaces for dispatchers and operators in monitoring and dispatch centers that operate 24/7/365. We implement the project from initial inquiry to final assembly at the customer's site.

We make photorealistic sketches of workplaces at each stage of the process, with elaboration of nuances and details.

We make photorealistic sketches of workplaces at each stage of the process, with elaboration of nuances and details.

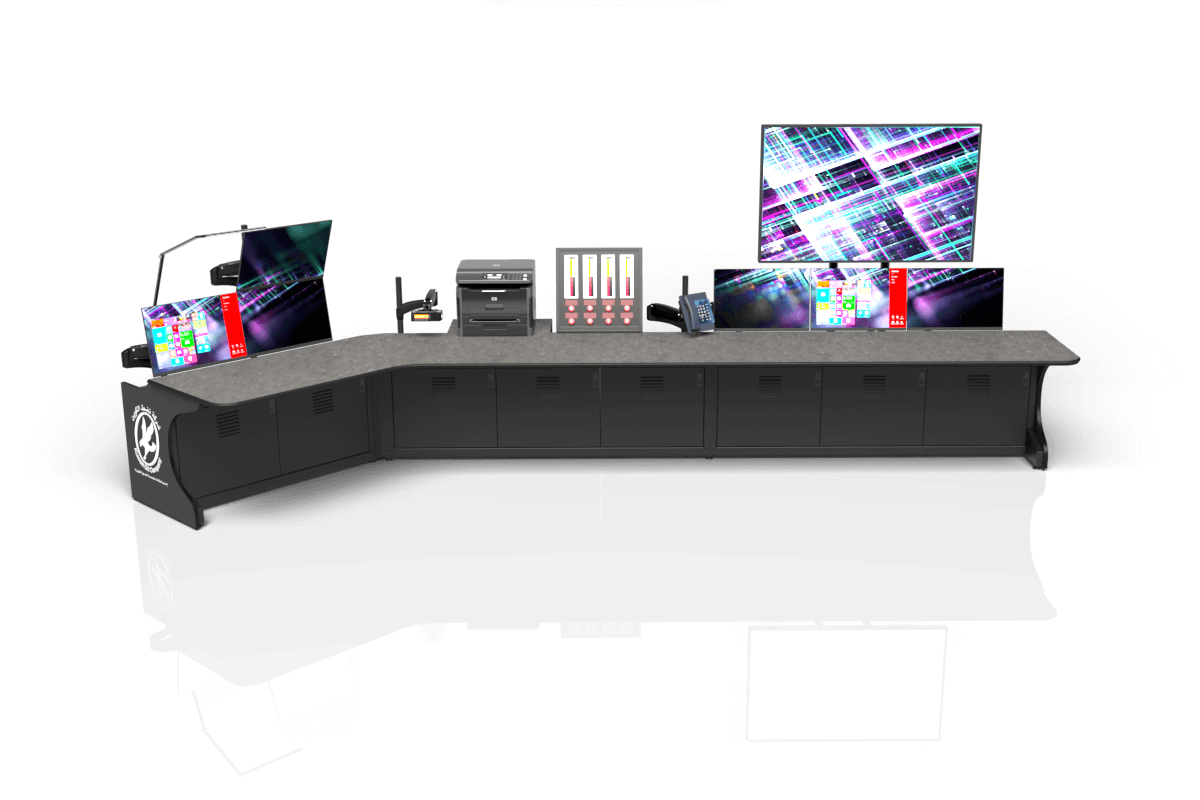

Unlimited Possibilities of Control Room Consoles RDM

Control room consoles RDM have a large number of functionalities and capabilities that allow

for the implementation of workplaces in any industry.

for the implementation of workplaces in any industry.

Convenient placement of technical documentation.

Placement of monitors in one and two rows.

Flat LED lamps do not interfere with looking at video walls.

The joint between the parts of the work surface is without gaps.

Unobstructed space under the work surface for easy movement.

Convenient placement of telephones and radios.

Auxiliary surfaces for record keeping journals.

Accessory surfaces for dispatch telephones and hands-free microphones.

We can place mortise elements such as emergency stop buttons.

Decorative side panels can be used to place company logo.

The technical compartments are equipped with dust and noise-proof ventilation openings.

Additional furniture for documents and staff belongings.

Emergency stop panels.

19" rack mount is 11U to accommodate patch panels, shelves and other equipment.

Pass-through access to the technical compartment (from front and rear).

Continuous ventilation system is equipped with temperature sensors.

Placement of CPUs with quick and convenient access for maintenance.

Quick access power and network outlets for connecting temporary equipment.

Convenient placement of office equipment.

Separate cable trays for power and network cables.

Ergonomic control room chair for 24/7 operator work with multiple adjustments.

Corner elements allow to give consoles absolutely any desired shape.

Placement of LED-panels from 40" to 70" for working with mnemonic circuits.

Separate brush cable entries for separate entry for power and network cables.

Durable Metal Frame and Wear-Resistant Materials

To achieve high-performance characteristics we use modern and wear-resistant materials

in the manufacturing of RDM dispatch consoles.

in the manufacturing of RDM dispatch consoles.

Parts are covered with high-quality Norwegian Jotun powder paint.

The metal parts of the supporting frame are made of steel with a thickness of 2.5 to 5 mm.

We use expensive fittings and accessories from the world's leading manufacturers.

Parts are manufactured on numerically controlled machines from Germany, Italy and Japan.

The top of the work surface is covered with Swiss homogeneous material called "Marmoleum" with antistatic and antibacterial properties. The thickness of the material is 2 mm, and it has the same pattern throughout its depth, which gives the material enormous advantages in terms of service life.

The edge of the work surface is covered with Italian ergonomic SafeGuard Edge. This edging protects the hands from injury, fatigue in the forearm area, and also protects the work surface itself from impacts of the armrests of the chair.

The monitor mounting system is made of heat-treated aviation aluminum which allows the placement of monitors weighing 120 kg per segment.

Convenient System of Equipment Placement

Equipment placement system allows to place a large number of different equipment within minimum of space,

each element of the system has 3D-adjustments.

each element of the system has 3D-adjustments.

Placement of monitors from 15" to 30" in one and two rows.

Ergonomic phone placement.

Professional control room LED lamps.

Convenient placement of radios.

Placement of analog control matrix panels.

Convenient placement of printers and other office equipment.

Placement of large-format LED-panels from 30" to 65".

Customized Configurations to Meet Customer Needs

Thanks to the modular structure of the control room consoles RDM you will get an individual configuration for your room and needs.

Industry-Specific Examples of Projects on Control Room Furniture RDM

We have a deep understanding and knowledge of different industries that allow us to realize any customer's goal.

Power Company Control Room

Situation Room of an Industrial Enterprise

Operator Room of Oil Pumping Stations

Petrochemical Center Control Room

Dealing Room of the Financial Center

Security and Dispatch Room in the Business Center

RDM Dispatch Consoles Are Used in

Leading Companies in the Eurasian Economic Union

We have completed projects for companies from many different industries.

|

We Transform Control Centers into a Modern and

Comfortable Workspace

The images below show the result of our work in the form "before/after" on the project of the control room for an energy company.

What Exactly Are We Doing to Achieve This?

We provide a full range of professional services for the arrangement of control rooms and organization of the workspace for dispatchers and operators.

How Do We Implement Projects on RDM Control Room Furniture?

Each project is divided into main stages and control points; in production the concepts of "Lean Production" are used,

which allow us to complete projects on time.

which allow us to complete projects on time.

First Inquiry

We will respond within 1 business day.

Task Setting

We will discuss your needs, clarify the task and begin its implementation.

Photorealistic Rendering

We will prepare a free photorealistic visualization inside the premises

and a detailed technical and commercial offer.

and a detailed technical and commercial offer.

Contract

We sign a detailed contract that takes into account all the nuances of the project.

Manufacturing

We produce in the shortest possible time from 6 to 12 weeks,

depending on the number and complexity of the consoles.

depending on the number and complexity of the consoles.

Delivery

We deliver anywhere in the world using our extensive experience in global logistics.

Assembly

We assemble anywhere in the world with our team of highly qualified engineers

with many years of experience.

with many years of experience.

Act of Completion

We sign the final act of completion of the project.

Warranty and Service

After the completion of the project we provide warranty and post-warranty service.

New Project

We are focused on long-term relationships on the implementation of projects anywhere in the world.

What Are Our Production Capabilities?

We have production sites with a machine park from well-known manufacturers, thanks to which we can produce

complex and fine looking products in the shortest time possible.

complex and fine looking products in the shortest time possible.

Control room consoles RDM are manufactured in St. Petersburg at several production sites using German, Italian, Swiss and Japanese equipment. Here are some of the machines used:

- Laser complex Trumpf TruLaser 5030

- Press brake Trumpf TruBend 3120

- Coordinate punching machine Trumpf TruPunch 1000

- Lathe Mazak Quick Turn Smart 200 ML

- Machining center SCM Morbidelli M100

- Additive complex SCM Morbidelli CX100

- Edgebanding complex SCM Olimpic K560

- Equipment for powder coating ITW Gema

Production is certified according to international standards ISO and BSI

Our production is certified according to the requirements: ISO 9001:2015; ISO 14001:2016; OHSAS 18001:2007 referring to the design, development, production, supply, installation and maintenance of professional control room furniture

|  |  |

Recent Work on RDM Control Room Furniture

Every month we post our fresh work.

| | Request the Cost of Your Project We will process your application within 1 business day, and you will receive a detailed commercial offer with a free photorealistic rendering of your control room. By clicking on the button, you consent to the processing of personal data and agree to the privacy policy. |